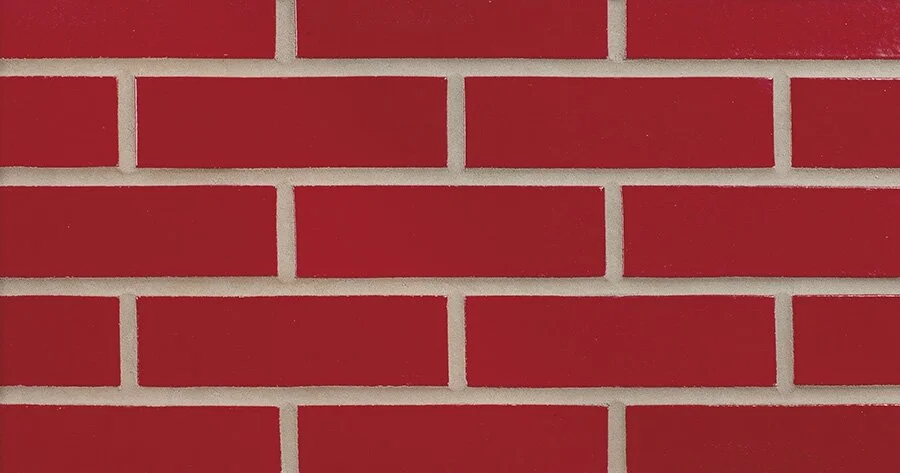

Glazed brick: The killer of all your brick stereotypes

/If you’re still not convinced that clay brick is more than just red and traditional — despite its thousands of color, texture, and size combinations and despite many, many contemporary brick designs — your brain is about to be wrinkled.

Have you ever used photo editing software with the slider bars for tinkering with the pic’s saturation, hue, temperature, etc.? Load a photo of a brick wall into your mental editing software, drag all those slider bars the right, and you’ll begin to have some sense of the dramatic impact of glazed brick! This is the side of brick you may never have seen before!

These brick are treated with a glaze, and sometimes several glazes, then fired to achieve extremely vibrant colors similar to what’s possible with ceramic tile. Glazes can be clear, translucent, or opaque, and can have a glossy, satin, or matte finish. Virtually no color is impossible with glazed brick, and because the glaze is fused to the brick in the kiln, the finish is extremely durable.

In fact, ASTM standards for glazed brick evaluate the product’s scratch resistance and hardness, its resistance to fading, fire resistance, and imperviousness. This last characteristic is measured in the lab by the degree to which dry ink can be wiped from the brick’s surface with a wet cloth. If you’re thinking that glazed brick’s pairing of vibrant colors and extreme durability would be ideal for schools, hospitals, and day care centers, you’re on the right track. But how about street level facades in areas with heavy pedestrian or bike traffic? Or, retail branding that is more permanent and dramatic than a bolt-on sign? The possibilities are endless!

Check out Technical Note 13 from the Brick Industry Association for all the technical details on designing ceramic glazed brick into your next project.